At Givens Engineering, we engineer and manufacture custom end effectors, roll handlers, hooks, tongs and lift assists for manipulators, robots, and cranes. End effectors are devices that are attached to mechanical or electrical lift assists and can be interchanged depending on the task or project at hand.

Our team of experienced designers, engineers, machinists, welders, and installers can create a custom end effector that will work best for your unique project. We design end effectors to be as lightweight as possible for fast and easy maneuvering. Every end effector is analyzed and approved by a Professional Engineer before fabrication begins.

What Are Mechanical Hooks and End Effectors?

Mechanical lifting tools like industrial end effectors and custom lifting hooks are vital for safe, precise handling. At Givens Engineering, we design end effectors for robots, manipulators, and manual lift assists that grip, lift, and position loads with ease.

As a trusted end effector manufacturer, we build robotic end effectors, mechanical hooks, and tongs that are lightweight, custom-fit, and built to optimize performance. Whether you need a robot end effector or manual lifting solution, we engineer each tool to match your system and workflow.

Have any questions about our custom end effectors?

Explore Our Range of Custom End Effectors and Handling Equipment

We use special grippers to lift parts with a latch or friction grip, customized to fit different shapes and models. Givens provides safe and efficient solutions for lifting various parts, especially in the automotive industry. We also handle heavy tasks beyond cars and offer a range of versatile tools for different purposes.

Roll handlers easily grip the inside of fiberboard and plastic core rolls. Our roll handling devices will improve the lifting and moving of extremely heavy rolls that can weigh several thousand pounds. A roll handler can assist the operator by providing both vertical and horizontal gripping of the roll. The handler can be equipped to both manipulators and cranes.

Givens Engineering manufactures custom hook lift assists to suit virtually every capacity and shape required. All hook and lift assists are made in accordance with the ASME B30. 20. Everything from cylinder scissor tongs, coil hooks, transmission lifts, hoists and more; trust Givens Engineering for the highest quality mechanical hooks and lift assists.

Vacuum systems are perfect for non-porous surfaces where gripping won’t work. Givens crafts custom vacuum lifting systems to handle diverse materials like metal sheets, wood doors, and glass. We ensure safe, ergonomic solutions that get the job done. Explore our vacuum tools—from adjustable suction cups for doors to lifting plastic dunnage. Our vacuum lifts streamline heavy material handling, empowering operations effortlessly.

If your parts are made of steel, magnets could be a great alternative. Magnet end effectors are versatile, grabbing thin, heavy, round, and large parts. They can even be customized to de-stack sheets and move heavy weldments in the same cell.

Our coil hooks, rigorously tested with a 4:1 safety factor, ensure reliability from certification to delivery. Engineered with an oversized counterweight for stability and equipped with precision technology, they promise balanced operation. For repairs, testing, or unparalleled efficiency in strength, trust our coil hooks.

We create special stainless steel tools for tough places like food or medicine. They’re tough, clean, and perfect for strict rules on cleanliness. Our tools use mostly stainless steel and welding, not much paint or screws. Past projects include steel tongs, a lifting cage, a drum tipper, and a food bag lifter.

Specialized tools for handling glass, solving safety challenges in construction and automotive industries. Our custom-designed end effectors efficiently lift and maneuver glass panes, ensuring operator safety and quick completion of tasks. With advanced vacuum systems, these versatile manipulators effortlessly handle large, heavy glass panes, providing precise tilting and rotation capabilities.

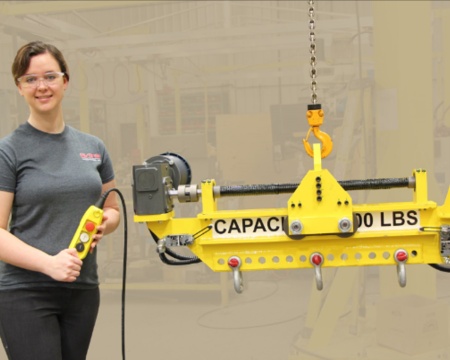

Each beam meets strict criteria: a 4:1 safety factor, adherence to or exceeding ANSI standards, certified welders, thorough stress point testing, load testing at twice the capacity, engineer-stamped assembly drawings, clear load labels, and detailed documentation with each shipped unit.

Custom end effectors for robots using pneumatic, electric, or vacuum power. These tools enable precise movements for parts in various positions, aiding industrial processes and accommodating different model variations. Experience efficiency with our advanced solutions: a high-capacity electric gripper integrated with an ABB robot and an advanced End-of-Arm Tool (EOAT) for precise sealant dispensing on a UR cobot (Collaborative Robots), elevating automation capabilities.

Our custom machine components are designed for durability and precision, including handles, control panels, and other integral parts. We engineer each component to integrate seamlessly with your lifting system for improved operator control and efficiency.

Elevate Your Operations with Mechanical Hooks and End Effectors

When precision, performance, and safety matters, Givens Engineering delivers. Our end effectors and hooks are designed to meet the demands of complex lifting, positioning, and handling tasks. As a trusted end effector manufacturer, we specialize in building custom solutions that integrate seamlessly with cranes, manipulators, and robotic systems. Whether you’re upgrading your system or engineering a new one, our robot end effectors offer the flexibility and reliability your operations require.

Have any questions about our custom end effectors?