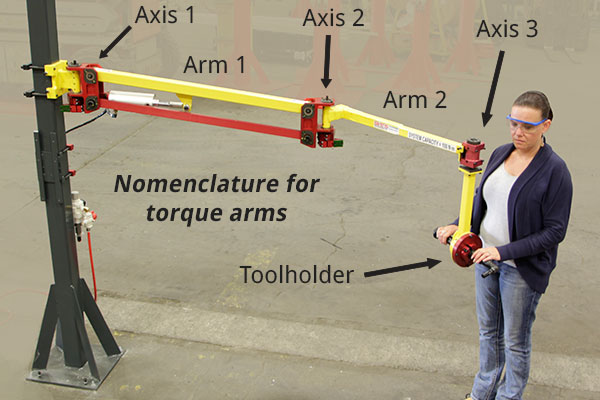

Torque Arms & Torque Reaction Arms

Torque arms are essential components used to absorb and counteract reaction forces during tool operation. For custom-made and highly engineered torque arms and tool-holders, trust Givens Engineering to design and manufacture the torque handling solution to suit your unique needs. All of our torque arm assemblies are proudly manufactured in Canada, ensuring high-quality craftsmanship and durability. Whatever the height, tool weight or torque required for your industrial production facility, there are virtually no limitations in terms of the customization we can incorporate into our specially designed torque arms.

What Do Torque Arms Do?

Torque Arms have 2 roles:

- They are made to absorb the torque that is generated during the process of tightening, which enhances safety, precision, and ergonomic performance for operators.

- Torque arms provide the necessary lift so that the nut-runner floats at all times on the end of the torque arm, following naturally horizontally and vertically.

Air-Floating Torque Arms with Custom Tool-Holders

At Givens Engineering, all our torque arms are specially manufactured in Canada to float on air and are exceptionally easy to maneuver. In general, the torque arm itself is mass-produced and stocked. The tool-holder, however, is custom-made for the specific fastening application at hand. The tool-holder can be very simple or can be more complex and include brakes or other unique functionalities.

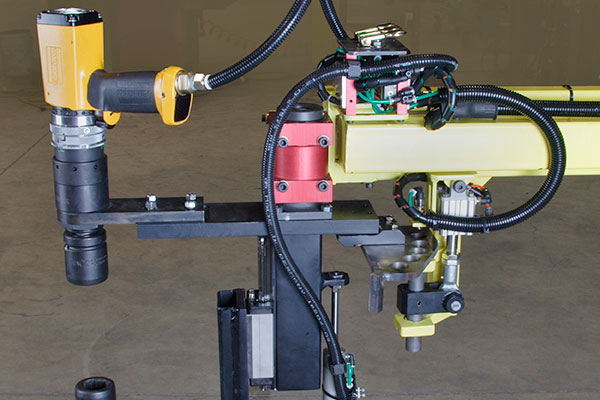

Nut-runner Servomotor and Gear Reducer for Torque Arms

In the photos on the right and below, the nut-runner, created by Givens Engineering, consists of a servomotor and gear reducer that are controlled by PLC and monitored through an HMI. The torque arm rises to a height of 4m on a pneumatic slide and applies a torque of 160Nm (120 ft-lb). The number of rotations and the torque are continuously monitored and logged. This advanced torque reaction arm is part of a custom-engineered torque arm design solution for demanding industrial fastening applications.

The trombone tool-holder for toque arms converges on both nut and bolt to fasten simultaneously.

1000Nm (750 ft-lb) of torque! Applied to large fasteners in a military vehicle. When you need really serious torque, we can provide a serious torque arm. Our heavy-duty torque reaction arms are part of our customizable assemblies.

Benefits of Torque Arms

- Torque arms are made to assist the operator in supporting the weight of the end effector/tooling

- The use of torque arms allows a workload to ‘float’, therefore there are no up/down push-buttons required, improving workflow efficiency

- Torque arms are lightweight and agile. The axis assemblies are made of anodized aluminum

- Soft-stops at the first and second axis are adjustable, providing enhanced control

- Torque arms are clamped to the post, the height can be adjusted

Accessories for Torque Arms

- Torque Brakes are available for the first and second axis, to eliminate drift in high-precision assemblies

- Bearing block assemblies are available at the end of the second arm allowing the end effector to rotate

- The parallel torque arms can be fitted with vertical travel stops

- The STD-TA series can be fitted with encoders to track the position of the tool so that individual torque values can be programmed for every fastener

- Torque Tubes can be used instead of torque arms – when it is necessary to hang a nut-runner from a crane

Differences Between Our Torque Arm Models

There are many torque arm models to choose from based on required torque, arm size, payload and typical reach needed for your manufacturing or production facility. Whether you’re in need of torque reaction arms for precise handling or a custom torque arm, our models are designed to suit various industrial requirements. The chart below demonstrates the differences between the main torque arm models and their unique lifting capacities.

| Arm Size | TA1 | TA2 | TA5 | TA10 | TA20 |

|---|---|---|---|---|---|

| Torque | 75ft-lb 100N-m | 150ft-lb 200N-m | 370ft-lb 500N-m | 750ft-lb 1000N-m | 1500ft-lb 2000N-m |

| Approximate Pay Load* | 10lb 5kg | 30lb 15kg | 50lb 25kg | 100lb 45kg | 150lb 70kg |

| Typical Reach | 4ft 1.2m | 5ft 1.5m | 7ft 2.0m | 8ft 2.5m | 10ft 3.0m |

* Pay Load = weight of nut runner + weight of tool holder

Total capacity is always a combination of torque and payload; always consult a Professional Engineer (P. Eng) before designing a torque arm.

Why Choose Givens Engineering

At Givens Engineering, we stand out for our commitment to providing high-quality, customized solutions for your torque handling needs. Our torque arms are expertly manufactured in Canada, ensuring precision, reliability, and durability in every product. Our team works closely with you to deliver the perfect fit for your unique operational requirements.

For more information regarding torque arms manufactured by Givens Engineering, download our informative brochure below and contact our team of professionals to discuss your unique needs.

Have any questions about our torque arms?